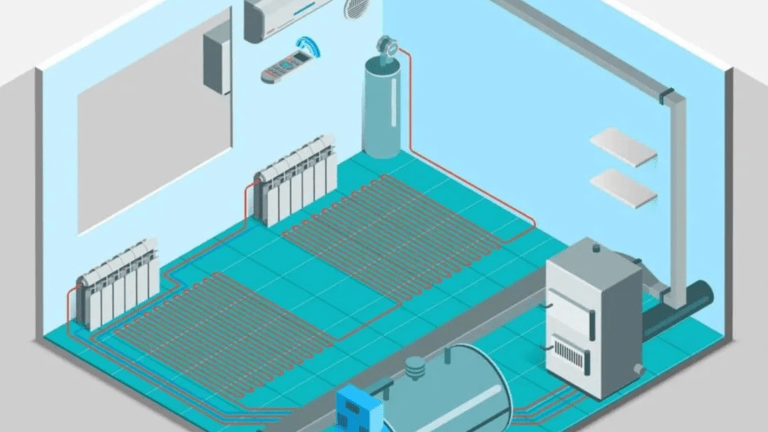

The company’s series of humidifiers have good atomization effects, finely atomized particles, fast vaporization and absorption by dry air, energy saving and environmental protection, stable performance, and high-cost performance, which are favored by new and old customers in various industries.

A new generation of the ultrasonic atomizing plate, using a high-quality ceramic vibrating plate, using an ultrasonic transducer to convert electrical energy into mechanical energy, under the action of high-frequency vibration of 1.7 million times/second, the water is atomized into ultra-high ≤ 5 μm Fine particles, forming water mist. And sent out through the circulating fan, so that the ambient dry air is absorbed and humidified.

To enable consumers to do a good job in the connection and installation of the humidifier and the water supply source, the humidifier and the air supply pipe after purchasing the equipment, reduce the failure rate of the equipment, reduce the cost of maintenance and replacement of parts in the later stage, and better utilize the humidification. It is recommended to read the instructions in detail and have a comprehensive understanding of the equipment.

Power connection of ultrasonic humidifier

Ultrasonic humidifier series products use a single-phase power supply. According to the power supply and power marked on the nameplate of the equipment, select a power cable with a wire diameter that meets safety regulations, and a matching air switch to connect and install the power supply. Or ask a qualified electrician to install it.

It is strictly forbidden to connect the power supply indiscriminately and use the equipment with hidden dangers.

Water supply connection of ultrasonic humidifier

Ultrasonic humidifier series products are supplied with tap water from a pipe network with a certain water pressure and can be used after connecting the corresponding interface.

The equipment is designed with a water inlet, drain outlet, and overflow outlet. Factory equipped with water filter (optional). The water filter is installed at the front end of the humidifier water inlet / the rear end of the tap water to ensure the cleanliness of the incoming water source. The water purifying filter element is a consumable item, and it can be purchased by itself when it is replaced later, or it can be purchased from the supplier, and the manufacturer offers it at a discount.

● The connection between the water inlet, the water quality filter, and the tap water shall be connected with the supplied hose;

● The water outlet has its valve, and the corresponding water pipe hose should be installed to connect with the drainage pipe in the space, which is convenient for cleaning the water tank in the future.

● The overflow port is a protective design to ensure that in the event of an accident, when the water intake cannot be controlled, the water will not overflow the water tank and flow to the ground in the space, hindering normal production.

● The use of softened water can effectively reduce the scaling phenomenon formed by the high-speed oscillation of the ceramic oscillating plate during the working process of the ultrasonic humidifier, which causes the metal ions contained in the water to be replaced. When the scale gathers around the vibrating plate, it will make the vibrating plate weak to vibrate and the atomization will be worse.

If there is no one to remove and maintain the scaling phenomenon, the working current of the ceramic oscillating plate will eventually increase, and the computer board integrated into the atomizing plate will be damaged. can not work. At this time, the ten-hole atomizing plate needs to be replaced (the cost is relatively high). If the scaling phenomenon can be cleaned up and eliminated in time, even if the vibration strength of some ceramic vibrating plates in the ten holes is not enough and there is attenuation, it is only necessary to replace the individual ceramic vibrating plates, and the cost is meager (see picture).

Therefore, when using tap water daily, pay attention to cleaning the water tank regularly, and be careful to clear the slight scale attached to the ceramic vibrating plate. If it is not used in the short term during the production process, or the statutory long holiday, the post operator needs to drain the humidifier water tank in time, dry the atomizing plate, and discharge the scale. When humidification is required, new water is injected to ensure the freshness of the water during the humidification process, thereby ensuring the cleanliness of the humid air. It can also effectively reduce the failure rate of the atomizing plate and prolong the service life of the equipment (ten-hole atomizing plate and ceramic oscillating plate).

● The atomizing plate of the ultrasonic humidifier has two water level sensors (see the two black plastic parts in the picture above). At the optimum water level, the atomization is strongest and the effect is best. Too high a water level (a lot of water) or too low a water level (too little water) will lead to fogging becoming smaller and smaller. Therefore, it is recommended to add tap water and control the water intake through the water inlet ball valve to ensure the best working water level. Manually adding water is not advisable and will not work.

Resin filter, a professional filter with softened calcium and magnesium ions, as shown in the picture,

Remarks: The above picture shows that after 2020, the softening water device has been changed to be used, and it is connected to the water inlet. By softening the inlet water, the oscillating sheet in the humidifier is not easy to produce scale during the working process. However, with this water-softening device, the water tank still needs to be cleaned regularly.

The connection between the ultrasonic humidifier and the air supply duct

[Declaration: It is strictly forbidden to directly start the humidification without adding the air delivery duct. The machine can be inspected in a short time. If the fog is not blown away for a long time, the humidifier will be in a high-humidity environment. The electrical components in the humidifier’s electrical box will be adhered to by condensation, causing a short circuit on the circuit board and burning the main board. Or the live operation of the equipment caused by condensation, which brings the hidden danger of unsafe use. 】

When connecting the ultrasonic humidifier to the air supply duct, pay attention to the following points:

1. The air supply duct should not be too long. Since the fan speed of the ultrasonic humidifier cannot be too fast, it is ensured that the water mist particles sent out are fine and easily absorbed by the air. This is the advantage of ultrasonic humidifiers. If the wind speed is too fast, the water mist particles in the pipe will collide with each other, and they will become large water particles, which will settle down and become water, which will return to the water tank, and the mist will become smaller. This is why pipes should not be too long. Usually, the effective piping distance of each mist outlet is preferably less than 25 meters.

2. The air supply duct should not take a “several” bend. Given the reasons mentioned in the first item, if there are too many bends in the pipe arrangement (several bends or right-angle bends), the wind resistance will increase. The water mist particles themselves are heavier, so it is difficult to send the water mist far away, thus causing the end Open the fog hole, no fog is sent out.

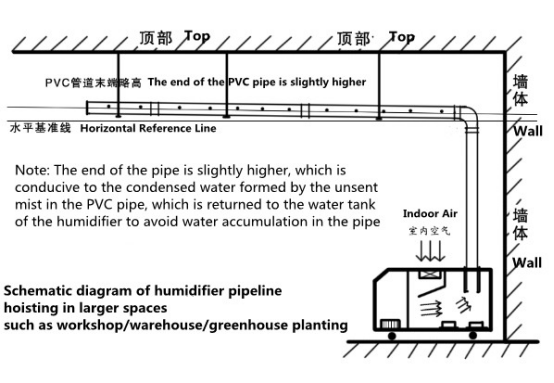

3. The end of the pipe must be higher than the front end of the pipe. Because the fine water particles are heavier, it is very easy to form condensed water in the air supply pipe. The condensed water accumulated in the pipe needs to be set up with the end higher than the front end, to return to the humidifier water tank. If the end is lower than the front end, the condensed water will accumulate more and more, ① the collected water will occupy the cross-sectional space of the air supply pipe; ② too much-accumulated water will cause bending, water leakage, dripping, and other phenomena at the connection of the hoisting pipe. (See attached image below)

4. How to open the mist outlet of the air supply duct. According to the size of the space used by the humidifier and the needs of the actual working conditions, the pipes are opened. In large spaces such as workshops, warehouses, and greenhouses, when hoisting and erecting air supply ducts, the spacing of openings is generally 800mm≤openings≤1500mm, and openings can be made on one or both sides of the air duct section at staggered positions. If it is in other small spaces such as vegetable display racks, fruit fresh-keeping warehouses, etc., the spacing of the openings is generally about 200mm≤openings≤300mm.

The number of openings on one or both sides of the air supply duct and how to make the openings. See the example picture for how to open the hole. The number of openings in each air supply duct should also be appropriate. Generally, the cross-sectional area of the 110mm cross-section round pipe ≈ the sum of the cross-sectional area of the openings on one or both sides of the entire pipeline, and the effect is better. Example: For a 110mm round pipe, no matter if it is one side or both sides, there should be no more than 35 fog holes with a 20mm opening. If there are few openings, the fog that comes out will be larger, and if there are too many openings, the fog will come out less, or the fog outlet at the end will not send out the fog.

Ultrasonic humidifier maintenance

Atomizer sheet maintenance

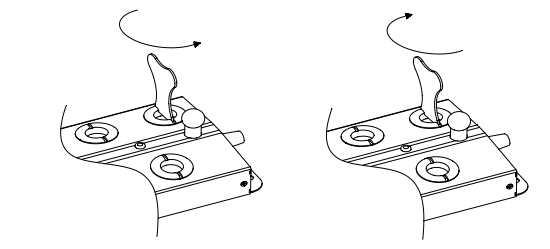

In the ultrasonic series products, the atomizers used are not suitable for atomizing corrosive liquids. To keep the atomizer in optimal working condition, it is recommended to clean the surface of the atomizer at least every two weeks. The cleaning method is: Drain the water in the atomization chamber, use the tool spoon to rotate counterclockwise to unscrew the wafer press ring (as shown in the figure), and use a clean soft cloth to clean the wafer; after cleaning, turn the wafer clockwise. The ferrule is screwed into the wafer cavity. If a resin filter has been used, the frequency of cleaning can be extended according to the actual frequency of use.

Water tank maintenance

1. Water tank maintenance: Please replace the clean water in the water tank every 7 days to reduce the deposition of scale in the atomizer.

2. Water tank cleaning: Clean the water tank once every 30 days. Before cleaning, please unplug the power plug to avoid electric shock. Cleaning method: Rotate the fixing screw of the water tank cover, open the water tank cover of the equipment, and clean it with a soft cotton cloth or a soft brush.

Ultrasonic humidifier pipeline erection legend

1) Pipes are erected in the textile workshop, and the mist outlet adopts a tee joint of 110 to 50

2) The fog effect of opening a hole on one side of the air supply pipe directly.

3) The picture below shows the effect of hoisting, opening and flogging of the edible mushroom.

4) The following picture is a schematic diagram of the pipeline erection in a large workshop, a schematic diagram of a single-sided opening or double-sided opening.

5) The following picture shows the installation effect of the humidifier during processing in the printing and dyeing industry

Thank you for choosing our company’s products, and welcome your valuable comments on our products and pre-sale/after-sale services.