Anti-Corrosion Dehumidifier Manufacturing Company

Made in China.

GetJoeAir specializes in manufacturing world-class anti-corrosion dehumidifiers. We help industries keep the air conditions stable to protect machinery, electronics, and infrastructure. Our dehumidification solutions offer uncompromising asset protection from expensive corrosion-related failures. We help businesses protect their heavy-duty equipment and industrial stocks in storage areas from deterioration from corrosion. Protect your capital, investments, and business now.

Schedule a free consultation and discover the anti-corrosion dehumidification systems designed for your specific needs.

High-Performance Anti-corrosion Dehumidifier Factory:

Effective Protection Against Corrosion

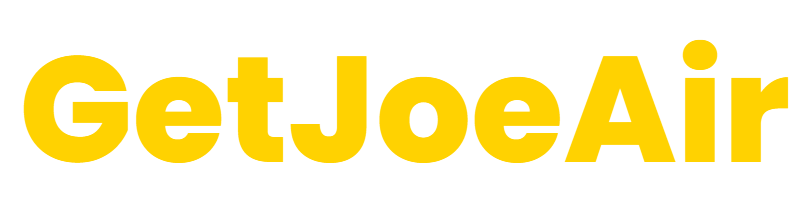

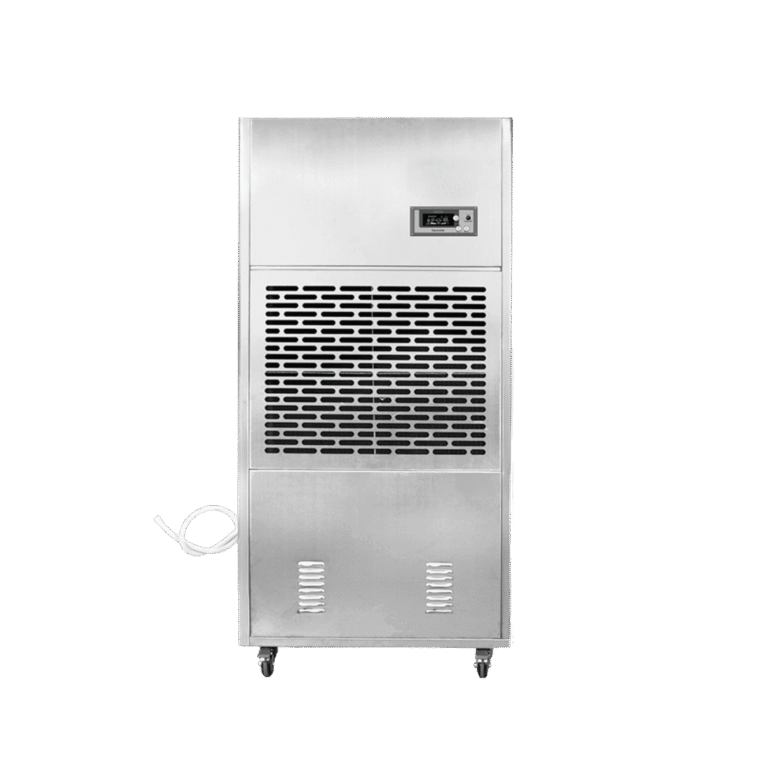

Moisture is one of the biggest threats to your valuable investments. Excess moisture may just appear as damp air, but it builds up rust, harms delicate industrial machinery, and accelerates the depreciation of your industrial assets and buildings. When it comes to protecting your equipment, electronics, and infrastructure, reliable air control is everything you can do. GetJoeAir’s anti-corrosion dehumidifiers are designed to stop rust and deterioration in industrial and commercial settings. The heavy-duty dehumidifier capacity of our dehumidifiers is capable of handling large-scale dehumidification for warehouses, manufacturing plants, and more. With automatic humidity control, extremely powerful mist output, and real-time digital feedback, our anti-corrosion dehumidifiers provide consistent humidity control.

Anti-Corrosion Dehumidifier Model List

Parameters and Catalog for GetAirify’s Anti-Corrosion Dehumidifier

Looking for anti-corrosion dehumidification solutions for huge industrial facilities? We specialize in protecting large-scale manufacturing environments through high-capacity anti-corrosion humidity control. Reach out to our team or explore our anti-corrosion dehumidifiers catalog. Our dehumidification specialists will ensure you find the right anti-corrosion system for your industry needs.

| Corrosion resistance level |

Commercial Dehumidifier Anticorrosion Description |

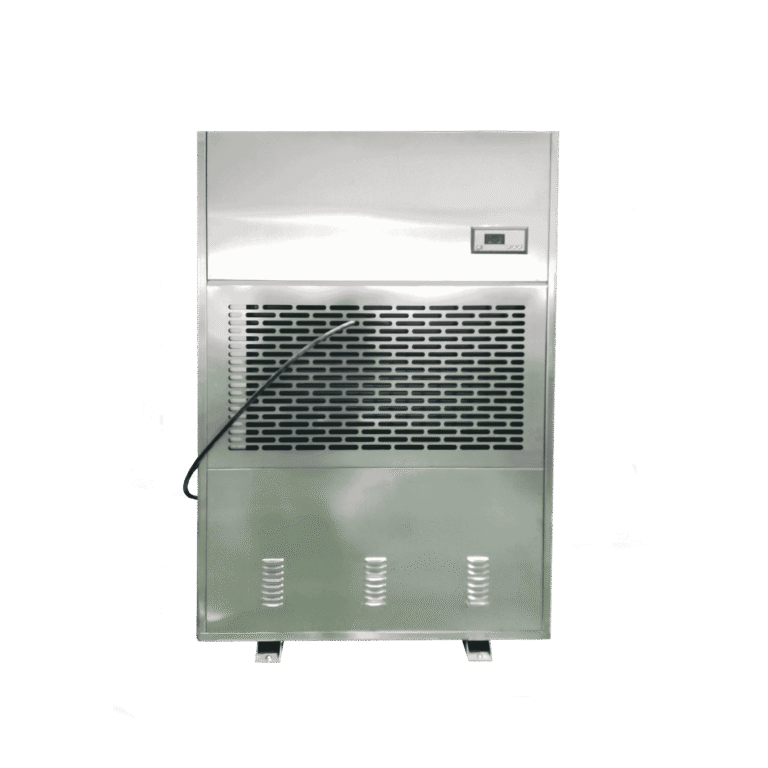

Industrial & Ceiling Dehumidifier Anticorrosion Description |

|---|---|---|

| Conventional | No anti-corrosion measures | No anti-corrosion measures |

|

Corrosion resistance level - Low |

1) Thickened copper tubes for the evaporator and condenser; 2) Stainless steel side panels; 3) Electrophoresis for the evaporator and condenser; |

1) Thickened copper tubes for the evaporator and condenser; 2) Stainless steel side panels; 3) Electrophoresis for the evaporator and condenser; |

|

Anti-corrosion grade -Medium |

1) Thickened copper tubes for the evaporator and condenser; 2) Stainless steel side panels; 3) Electrophoresis for the evaporator and condenser; 5) Stainless steel drain pan; |

1) Thickened copper tubes for the evaporator and condenser; 2) Stainless steel side panels; 3) Electrophoresis for the evaporator and condenser; 4) Enclosed motor box and control panel; 5) Stainless steel drain pan; |

|

Corrosion resistance level - High |

1) Thickened copper tubes for the evaporator and condenser; 2) Stainless steel side panels; 3) Electrophoresis for the evaporator and condenser; 6) Entire unit constructed entirely of stainless steel. |

1) Thickened copper tubes for the evaporator and condenser; 2) Stainless steel side panels; 3) Electrophoresis for the evaporator and condenser; 4) Enclosed motor box and control panel; 6) Entire unit constructed entirely of stainless steel. |

* The tables can slide right (tablet and mobile)

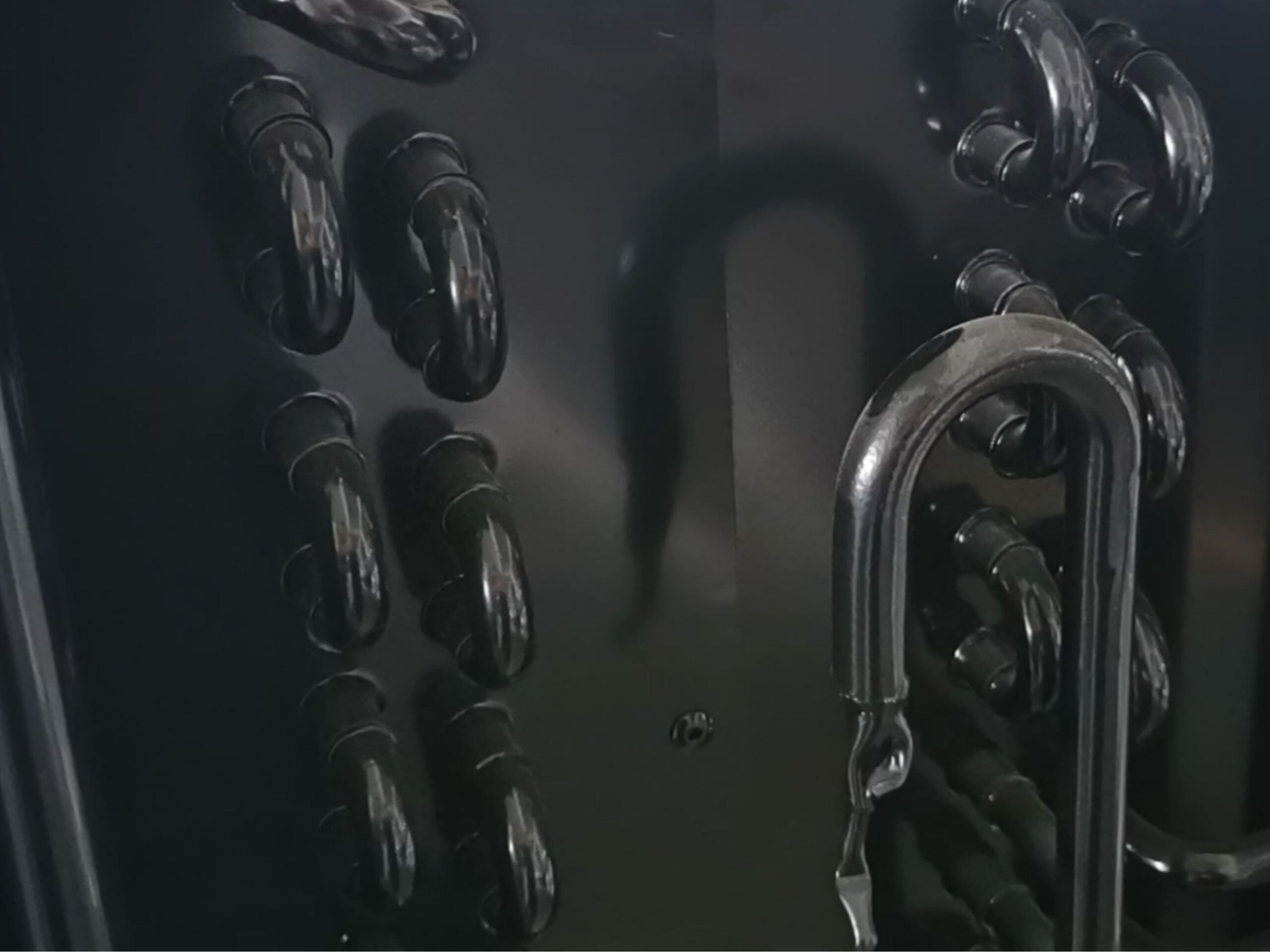

Thickened Copper Tubes For The Evaporator And Condenser

The thickened copper tubes for the evaporator and condenser are used in our anti-corrosion dehumidifiers. These latest technology dehumidifiers are designed to offer exceptional durability and extended service life. This reinforced copper construction is made to enhance efficiency. It allows superior moisture removal and consistently dry conditions across dense industrial environments that are more prone to corrosion-related damage. This feature makes your business reduce downtime and save real costs. It provides reliable corrosion protection in demanding environments–protecting your long-term investments.

Additional Durability with Corrosion-Resistant Stainless Steel Plates

GetJoeAir’s anti-corrosion dehumidifiers come with robust stainless steel side panels. These panels provide additional and lasting protection and uncompromising strength to our range of dehumidifiers. The stainless steel panels make GetJoeAir’s anti-corrosion dehumidifiers highly resistant to the build-up of rust. This feature makes our dehumidifiers more reliable and durable, even in the most moisture-heavy industrial settings. These plates add toughness and structural integrity to our range. Stainless steel plates help reduce downtime by adding resilience to dehumidify in corrosion-prone industrial environments.

About GetJoeAir Advantages

GetJoeAir is a leading dehumidifier supplier in China, boasting a professional R&D team and a great production team.

Our R&D team, comprised of 5 members, is dedicated to enhancing dehumidifier efficiency. By the end of 2023, we had developed over thirty models suitable for various industrial settings, including the food industry, pharmaceutical industry, cold storage units, explosive storage facilities, and more.

Following design, our professional production team takes over, ensuring all models are transformed into top-quality industrial dehumidifiers for sale.

When your business requires an industrial commercial dehumidifier, trust GetJoeAir. Contact us now!

Industries That Benefit Most from GetJoeAir Anti-Corrosion Dehumidifiers

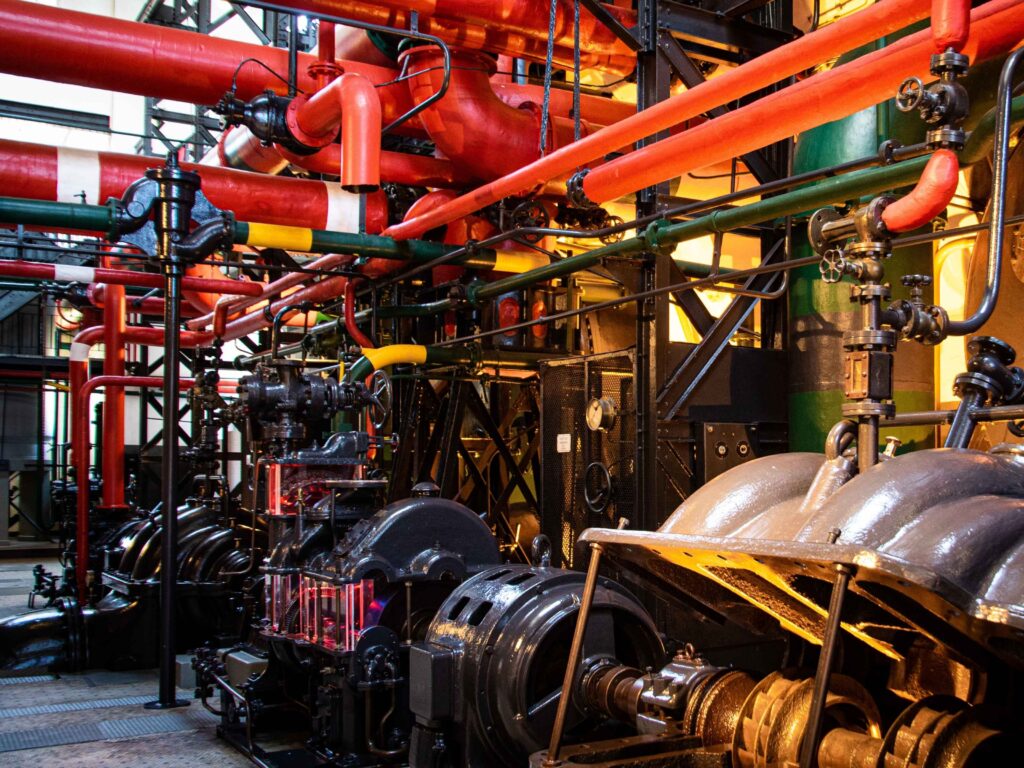

Manufacturing Industry

In the manufacturing industry is somewhere the internal environment is moist-heavy. It makes it prone to the build-up of rust and corrosion, which in the long run not only affects the business operations but also building, expensive industrial equipment, business assets, tools, products, and materials. This, in return, causes downtime and huge losses to your business. Anti-corrosion dehumidifiers help manufacturing industries escape these damages simply by maintaining the air quality and humidity levels.

Electronics & Telecommunications

All the businesses related to the electronics industry involve heavy-duty systems and equipment that must stay fully functional throughout the year. Your business runs until you protect the sensitive electronic boards, huge servers, and telecommunication equipment. The buildup of rust causes damage to your systems, and so causes huge hurdles on your way to functionality. Our anti-corrosion dehumidifiers help electronics businesses maintain dry internal environmental conditions, which prevent malfunctioning and signal disruptions due to moisture.

Healthcare and Pharmaceuticals

The pharmaceutical businesses are to rely heavily on their supply chains. They are supposed to maintain supplies of medicines and chemicals stored in a way that keeps them intact. Moisture can cause huge trouble and wash out the entire business continuity. It can damage the stored chemicals and medical devices. Therefore, a certain humidity level is required in labs and cleanrooms to maintain GMP compliance. GetJoeAir’s anti-corrosion dehumidifiers help healthcare and pharmaceutical businesses stay compliant to GMP.

Food Processing and Beverage Industry

The food and beverage industry is required to follow the industry standards of food quality and hygiene. When the environment is more humid than it should be, it causes damage to industry equipment, raw materials, and packaged items, including stock and raw materials. Our anti-corrosion dehumidifiers help businesses prevent the humidity-related damage and spoilage in the storage and processing areas. We help food and beverage businesses stay compliant with industry standards of quality.

Energy Industry

The energy industry involves the utilization of control panels, transformers, turbines, and switchgears. Moisture control is critical to the continuous supply of electricity. Our anti-corrosion dehumidifiers ensure functional reliability, keep the critical infrastructure intact, and extend the lifespan of equipment by avoiding equipment degradation.

GetJoeAir helps you ensure the uninterrupted production and distribution of energy. We help the energy industry lower long-term maintenance costs caused by corrosion-related issues.

Salt-ridden Marine Industry

Anti-corrosion dehumidifiers are irresistible for the marine and shipbuilding industry. It dehumidifies and removes dampness that prevents salt crystallization. We help huge cargo holds and engine rooms stay rust-free. Our range of anti-corrosion dehumidifiers helps this industry by keeping the steel frameworks, navigation systems, coatings, and machinery free from moisture.

Lumber Drying Rooms

During the drying process, wood releases gases that have corrosive potential. This is somewhere where corrosion-resistant dehumidifiers are inevitable. Our anti-corrosion dehumidifiers facilitate the wood drying process while keeping the wood intact. Moreover, our devices protect your machinery, drying rooms, and infrastructure from the corrosion buildup caused by high humidity levels in drying rooms.

What specific models of anti-corrosion dehumidifiers are available?

All the models of GetJoeAir’s commercial, industrial, and ceiling-mounted dehumidifiers can be customized according to your industry needs. Moreover, all of our dehumidifiers can be upgraded to anti-corrosion dehumidifiers to sustain in extremely damp environments.

Can these dehumidifiers last longer under extreme and corrosion-prone environments?

Yes. GetJoeAir’s anti-corrosion dehumidifiers are tailor-made to sustain and effectively pull out excessive moisture without being corroded themselves. In a corrosive environment, using a traditional dehumidifier on the market will cause the dehumidifier to corrode and malfunction after a short period of use. Therefore, in some extremely corrosive industrial settings, we recommend anti-corrosion dehumidifiers.

How are anti-corrosion dehumidifiers made?

At GetJoeAir, anti-corrosion dehumidifiers are built differently to last longer. These dehumidifiers are made from stainless steel panels to ensure high-grade corrosion resistance. The internal parts come with anti-corrosive coatings. These units are designed to withstand corrosion-prone environments. These units not only protect the vicinity but also last longer in such harsh environments where regular dehumidifiers fail to perform.