A dehumidifier that is well-equipped and up-to-date will definitely work in a cold room. There are many industries with a must cold storage, like the food and beverages industry or the pharmaceuticals. Dehumidifiers are crucial in these cold rooms to maintain a risk-free, suitable, preserved environment for stocking up goods.

Working Of Dehumidifiers In Cold Spaces

The humidity level of a room is not entirely connected to the warm weather as it is generally believed. The cold rooms are not wholly moisture-free. To give prior protection against the possible after-effects of increased humidity, the dehumidifiers are installed in the cold rooms.

It’s only that cold weather may be a hindrance in the effective working of the dehumidifiers, but if you are using a reliable brand of dehumidifier, it can prove to be as efficient in removing the excess humidity from the cold space as it may work in a warm temperature.

What Is The Best Dehumidifier For Cold Room?

The two most suitable types of dehumidifiers for industrial use are refrigerants and desiccants. The only difference between them is the mechanism by which they work to remove the moisture level from the air. Let us sum up each of them for you to have a more profound understanding to choose the right one:

Types Of Dehumidifiers

Refrigerant (Compressor-Based) Dehumidifiers

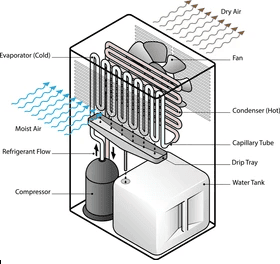

The working mechanism of this type of dehumidifier is closer to that of a fridge. It creates a cold surface to condense the moisture from the air. The air is drawn in with the help of a fan in the dehumidifier. The moisture from the air is then condensed on a cold surface of the metal plate and ultimately dripped into the water tank for disposal, reducing the relative humidity in the room to the normal level.

Although it is widely considered that refrigerant dehumidifiers aren’t meant for low-temperature usage, as they already involve cold metal plates, the fact is that they can be effective in normalizing the relative humidity of a space with just the right combination of competitive high-performing components.

Desiccant Dehumidifiers

The working mechanism of the desiccant type of dehumidifier is different. In this type, a material is used as an absorbent of moisture from the air. A slowly rotating wheel with the desiccant substance is used to drive out the moisture from the air.

The moisture is condensed and disposed of through the water tank. This type of dehumidifier is considered more effective in providing adequate coverage to cold rooms due to the involvement of substances like silica-gel or calcium chloride instead of any metal plate treatment.

However, as attractive as it seems, some drawbacks have made this type unsuitable for industrial usage. They need more power to work in comparison with refrigerant dehumidifiers and aren’t budget-friendly. Also, when compared in terms of reliability and functionality, the desiccant dehumidifiers far lagged behind the refrigerant(compressed-based) dehumidifiers.

Low-Temperature Refrigerant Dehumidifiers

This type can be termed a sub-category of refrigerant dehumidifiers with a specialized technique for effective operation in low temperatures. They work in a more refined form than the standard compress-based dehumidifiers.

While the minimum temperature of the compress dehumidifiers is usually 65 F, this type can operate effectively at a few degrees above temperature than the freezing point. They specialize in cold storage and warehouses meant to stock up goods.

Why Is There A Need For Dehumidification In Cold Rooms?

The need for dehumidifiers is not confined to only warm spaces. There are specific cases where a cold room or storage may contain moisture. The moisture control in these cold rooms or storages is mandatory for safety concerns and to ensure undamaged products.

The temperature below 50 F may cause ice frost on the products and their outer packaging if the space’s relative humidity is higher. There are many reasons for moisture being present in a confined cold room. Opening the door for cleaning or routine work, any machinery working, etc.

If there is increased relative humidity in the room, the moisture content in the air may lead to ice build-up on the floor, walls, and even on the goods and stock.in some rare cases, it may lead to mold growth in the stock or damage the packaging.

The ice buildup on the floors may pose a serious hazard for the workers as it may cause the floor to be slippery. The ice can also damage your equipment or freezer coils and lightning setup, putting your equipment at risk of corrosion.

Important Determinants To Be Considered For Using A Dehumidifier In A Cold Room

There are some points to be taken into account before opting for a dehumidifier that works in cold temperatures. Let us make it easy for you by summarizing them most efficiently.

Moisture Level Of Your Space

Before installing a dehumidifier, you should know the source and level of humidity in your facility. Specific types of dehumidifiers work well with different humidity levels. You can only select the most appropriate if you have complete know-how of the relative humidity level of the room.

Temperature Range

The temperature level of each type of food or pharmaceutical product is different. It may be that certain frozen foods need lower moisture than medicines. You must be fully aware of the ideal temperature of your type of product and then install the kind of dehumidifier accordingly.

Desired Level Of Humidity

Before buying any dehumidifier, always check the level of humidity it can provide. It must be capable of decreasing humidity levels to your specifications and be efficient enough to work well in a chilling space.

Proper Ventilation

Dehumidifiers need proper ventilation to work effectively. Not only that, they need an appropriate space for the airflow that has to be sent back to the room after removing the moisture content. Any hindrance to airflow or ventilation may cause the dehumidifier to block or choke.

Power-Conservation

The power-conserving factor must not be ignored as you plan to use the dehumidifier for industrial use on a large scale. The type and brand of dehumidifier that provides the maximum benefit with the minimum power usage must be chosen.

Cost-Effective Solution

The preferred type of dehumidifier must be cost-effective. Not only that, it uses less power, and its maintenance and care must not be so expensive that it increases your overall production cost instead of facilitating you.

Apart from these, there are many other determinants to be looked for while installing the dehumidifiers. The size of the dehumidifier and the proper installation also need to be considered if one desires to achieve the maximum benefits from it.

Final Words

The need for dehumidifiers cannot be overlooked if you want a safer aura and undamaged goods at your end. When searching for a reliable name for dehumidifiers, we can rightly claim to offer a premium range of low temperature industrial dehumidifiers. Not only that, but we also provide complete expert assistance about their suitability and working mechanism for your type of use. Let’s get connected!