Are you tired of your electronics feeling like they’ve been through a Sahara sandstorm? Do you want to protect your sensitive equipment from static electricity? Have you ever considered a wet film humidifier for your industrial workspace? No? Well, hold on to your hats, because I’ve got some information that will blow your socks off (if you’re wearing any)!

Introduction

Briefly introduce the benefits

If you’re looking for an effective way to increase humidity levels in your home or workplace, a wet film humidifier is an excellent option. These cooling devices use a thin, water-saturated material/wet film material to add moisture to the air, resulting in a more comfortable and healthy indoor environment. In this blog post, we’ll show you how to use a wet film humidifier properly.

In an industrial setting, maintaining the proper level of humidity is critical for protecting electronic equipment and preventing damage due to static electricity. Wet film humidifiers can effectively control humidity levels and prevent static buildup, which can damage sensitive electronics.

Using a wet film humidifier in a warehouse can also help prevent damage to stored goods due to dry air. This can be particularly important for materials that are sensitive to humidity, such as paper, textiles, or wood products.

The use of wet film humidifiers can also provide benefits to workers in an electronic workshop or warehouse, as they can help create a more comfortable and productive work environment through the creation of a uniform water film. However, it’s important to note that they are not intended to improve air conditioners and quality in the same way as residential humidifiers. In addition, it’s important to ensure that the humidifier is not interfering with any existing air conditioning unit in the space.

Explain the purpose of the blog post

The purpose of this blog post is to educate readers on the benefits of using a wet film humidifier, particularly in industrial settings such as electronic workshops and warehouses. Readers can expect to learn about the advantages of maintaining a healthy level of humidity, the specific benefits of using a wet film humidifier, and how it can effectively protect their electronic equipment and stored goods from damage. The post will also cover the low-maintenance and energy-efficient nature of wet film humidifiers and how they can save money and reduce carbon footprints. Ultimately, readers will gain a better understanding of the value of investing in a wet film humidifier for their industrial needs.

Understanding Wet Film Humidifiers

Define what a wet film humidifier is and how it works

A wet film humidifier is a type of industrial humidification system that can be used in conjunction with an air conditioning unit to add moisture to the air. The wet film is made up of a layer of cellulose material/wet film material that is continuously wetted by a water source. As air is drawn through the humidifier, it passes over the wet film, causing the water to evaporate and add moisture to the air. The humidifier is designed to control the humidity level of a specific area by adjusting the speed at which the dry air passes over the wet film. This process ensures that the air remains at a consistent and comfortable level of humidity, which is beneficial for electronic equipment and stored goods. Wet film humidifiers are known for their low maintenance and energy efficiency, making them a popular choice for industrial settings.

Discuss the wet film humidifiers’ control logic

The control logic of a wet film humidifier is designed to ensure that the humidity level of the controlled area remains at a set point. This is typically achieved by measuring the relative humidity of the air and comparing it to the desired set point. The control logic then adjusts the speed at which the air passes over the wet film to increase or decrease the amount of moisture that is added to the air.

Some wet film humidifiers use a simple on/off control, where the unit turns on when the humidity level falls below a certain threshold and turns off when the humidity level reaches the desired set point.

In summary, the control logic of a wet film humidifier plays a critical role in maintaining a consistent and comfortable humidity level in the controlled area. The type and form of control logic used depends on the specific humidifier and the requirements of the application.

The difference between wet film humidifiers and ultrasonic humidifiers.

Wet film humidifiers and ultrasonic humidifiers are two types of models of humidifiers that are commonly used to add moisture to indoor environments. Wet film humidifiers use a uniform water film that is constantly wetted by a water source, while ultrasonic humidifiers use high-frequency vibrations to create a fine mist that is released into the air.

One key difference between these two types of humidifiers is the way they operate. Wet film humidifiers rely on the natural process of evaporation to add moisture to the air, while ultrasonic humidifiers use a mechanical process to produce a mist. This means that wet film humidifiers do not require any additional electricity to operate, making them more energy-efficient than ultrasonic humidifiers.

Another difference is the way they distribute moisture. Wet film humidifiers release moisture slowly and steadily over time, resulting in a consistent level of humidity. Ultrasonic humidifiers, on the other hand, can release moisture more quickly and in larger quantities, which can sometimes result in over-humidification.

Additionally, wet film humidifiers are known for their low maintenance requirements, as they do not require frequent cleaning or replacement of parts. Ultrasonic humidifiers, however, may require more maintenance due to the build-up of minerals in the water tank.

Overall, both wet film and ultrasonic humidifiers have their advantages and disadvantages. Choosing the right type of ultrasonic humidifier depends on the specific needs and preferences of the user.

What is wet film material?

A wet film material is a thin, water-saturated material used in wet film humidifiers to add moisture to the air. It is typically made up of a layer of cellulose material that is continuously wetted by a water source. As air passes through the humidifier, it passes over the wet film, causing the water to evaporate and add moisture to the air. This process helps to increase the humidity levels in a room, which can be beneficial for a variety of purposes, such as improving air quality and preserving goods in a warehouse.

How to Use a Wet Film Humidifier

Step-by-step instructions on how to set up the humidifier

Setting up a wet film humidifier is a straightforward process that can be completed in a few simple steps. Here is a step-by-step guide to help you get your humidifying started:

Determine the appropriate location for the humidifier. The ideal location should be near a water source and electrical outlet, and away from any heat sources or direct sunlight.

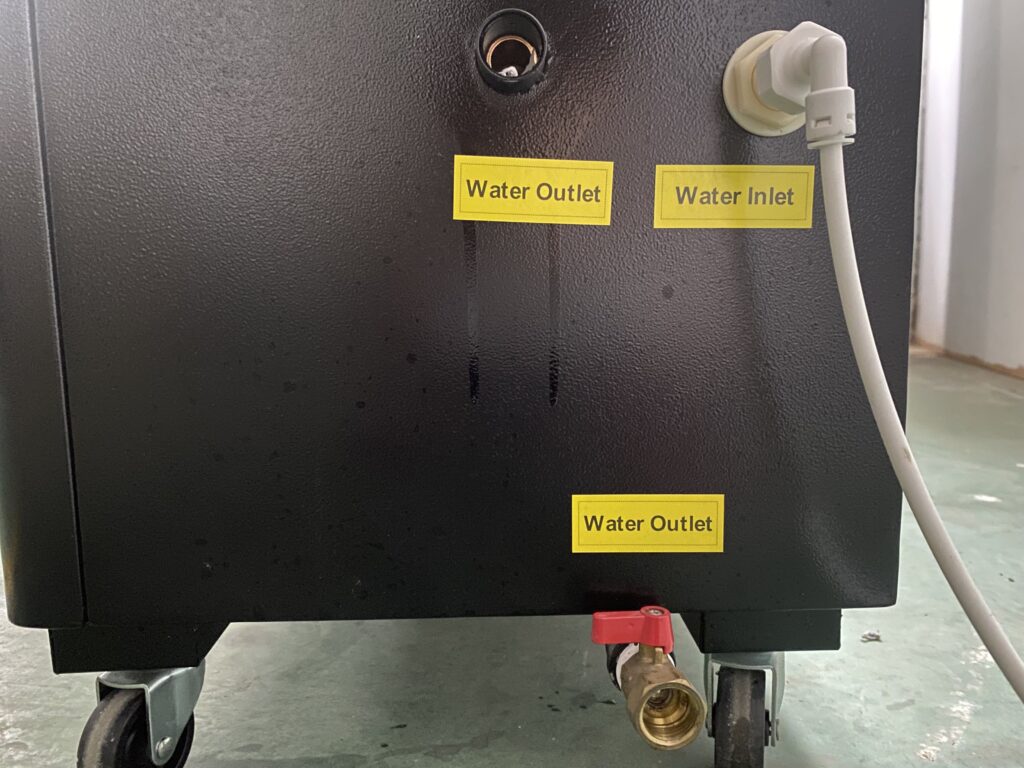

Install the water supply line. Connect the water inlet pipe to the humidifier according to the manufacturer’s instructions. Make sure to turn off the water supply before making any connections.

Fill the water tank. Open the water tank and fill it with clean and fresh water in the water inlet pipe. Please connect circulating water well to the water supply and add water actually, the added water by hand place only use it when urgent, not daily time.

Distilled water is recommended. Avoid tap water or hard water, which can cause mineral buildup and affect your humidifier’s performance.

Turn on the power. Plug in the humidifier and turn it on.

Set the humidity level. Adjust the humidity level according to your preferences using the humidistat or control panel.

Monitor the humidity level. Keep an eye on the humidity level and adjust the humidifier as needed to maintain a comfortable and healthy level of humidity.

Clean the humidifier regularly. Regularly clean and maintain the humidifier to ensure optimal performance and longevity. Follow the manufacturer’s instructions for cleaning and maintenance.

By following these simple steps, you can set up a wet film humidifier and enjoy the benefits of comfortable and healthy indoor air. Remember to always follow the manufacturer’s instructions and consult a professional if you have any questions or concerns.

Here, we do a video for your easy to understand.:

Key operation procedure:

Adjust the humidity level, for example: 70%RH

Firstly, press the” power” botton, we cans see room humidity is 45%RH on the screen.

Then, press ”humi+” to up to 70%RH, and it will Keep flashing. When we continute to press “humi+” botton, you will find when it up to 95%RH, the humidity range starts at 20%. So, we can see the humidity range is 20%RH~95%RH.

Lastly, the circle is flashing, means the wet film humidity is working.

Then, set aim humidity to 40%RH. Press “humi-” to 40%, and the circle is not flashing, which means has reached the humidity. And it turns into the ventilation mode and works automatically.

Explain how to adjust the humidity levels according to the user’s preference

Adjusting the humidity level in a wet film humidifier is a simple process that can be done using the humidistat or control panel. Here are the steps to follow:

Locate the humidistat or control panel. The humidistat is a device that measures the humidity level and regulates the operation of the humidifier accordingly. The control panel is a digital or analog interface that allows you to adjust the settings of the humidifier.

Determine the desired humidity level. The ideal humidity level for most industrial environments is between 50% and 70%. However, the optimal level may vary depending on goods preference, the size of the room, and the outdoor climate.

Adjust the humidistat or control panel. Use the humidistat or control panel to adjust the humidity level to your preferred setting. Follow the manufacturer’s instructions for adjusting the settings.

Monitor the humidity level. Keep an eye on the humidity level using a hygrometer or the humidistat. If the humidity level is too high or too low, adjust the settings accordingly.

Fine-tune the settings. Once you have adjusted the settings, observe the humidifier’s operation and make any necessary fine-tuning to achieve the desired humidity level.

Remember to avoid setting the humidity level too high, as this can promote the growth of mold and mildew. It is also important to monitor the humidity level regularly and adjust the humidifier as needed to maintain a comfortable and healthy indoor environment.

Tips on how to properly maintain the humidifier to ensure its longevity

Proper maintenance is essential to ensure the longevity and optimal performance of a wet film humidifier. Here are some tips on how to maintain your humidifier:

Exchange the water. Clean the water in the water tank, and use the refreshing water regularly. Recommend changing the circulating water tank about 1 time around in 10 days. The exact time according to the use situation. Also, when not using the wet film, please drain all the water inside.

Clean the humidifier regularly. Clean the wet film, water tanks, and other components of the humidifier regularly to prevent the buildup of mineral deposits, mold, and bacteria. Follow the manufacturer’s instructions for cleaning the humidifier.

Change the wet film regularly. The wet film needs to be replaced periodically to ensure optimal performance.

Use clean water. Use clean, distilled water in the humidifier to prevent mineral buildup and bacterial growth. Avoid using tap water or hard water, which can cause mineral buildup and affect the performance and function of the humidifier.

Monitor the water level. Make sure the circulating water pump supply is connected well and can add water automatically; at the same time, recheck the display about the water level shown on the monitor, sure the water tank it’s not empty.

Check for leaks. Regularly check for leaks in the humidifier’s water supply and drainage systems. Repair any leaks immediately to avoid damage to the humidifier and surrounding areas.

Schedule professional maintenance. Schedule periodic professional maintenance for your humidifier to ensure optimal performance and longevity. A professional technician can clean and service the humidifier and make any necessary repairs or replacements.

By following these tips, you can ensure that your wet film humidifier operates effectively and efficiently for many years to come.

Benefits of Using a Wet Film Humidifier、

Discuss the advantages of using a wet film humidifier in different environments

A wet film humidifier is a powerful tool for maintaining the ideal humidity levels in different environments. Here are some advantages of using a wet film humidifier for high humidity air in different environments:

Industrial Environments: Wet film humidifiers are commonly used in industrial environments such as factories, warehouses, and workshops to control humidity levels. Maintaining the right humidity levels in these environments can help prevent damage to machinery, products, and materials. A wet film humidifier can also improve employee comfort and productivity.

Commercial Environments: In commercial environments such as hotels, hospitals, and offices, a wet film humidifier can help maintain the humidity sensors for a comfortable and healthy environment. Proper humidity levels can help reduce the spread of airborne viruses and bacteria, improve air quality, and reduce the risk of respiratory problems.

Residential Environments: In homes, a wet film humidifier can help alleviate dry skin, throat irritation, and other health problems caused by low humidity levels. It can also help protect wooden furniture and other items from damage.

Agriculture: Wet film humidifiers can also be used in agriculture, particularly in greenhouses, to help maintain ideal humidity levels for plant growth. Maintaining the right humidity levels can help improve plant yield, reduce plant stress, and prevent diseases caused by dry air.

Museums and Art Galleries: In museums and art galleries, a wet film humidifier can help protect valuable works of art and artifacts from damage caused by dry air. Proper humidity levels can help prevent the cracking, warping, and fading of paintings, sculptures, and other artifacts.

In conclusion, a wet film humidifier is a versatile tool that can be used in a wide range of environments to maintain ideal humidity levels. From industrial settings to residential homes, the benefits of using a wet film humidifier are clear.

Highlight how the humidifier can improve air quality, and preserve warehouse goods

The wet film humidifier is primarily used for humidity control in industrial settings like warehouses and electronic workshops.

However, the use of a wet film humidifier can still benefit the environment by preserving goods stored in a warehouse. By maintaining the appropriate humidity level, goods like paper, textiles, and electronics can be protected from damage caused by excessive moisture or dryness.

For example, in a textile warehouse, a wet film humidifier can help prevent fibers from becoming brittle or developing static electricity, which can damage the fabrics. In an electronic workshop, maintaining the proper humidity level can prevent the buildup of static electricity, which can damage sensitive electronic components.

In summary, a wet film humidifier may not directly improve air quality, but it can help preserve goods by controlling the humidity level in a warehouse or electronic workshop.

Conclusion

In this blog post, we discussed wet film humidifiers, which are industrial-grade humidifiers used for humidity control in settings like warehouses and electronic workshops, and provided step-by-step instructions on how to set them up.

We also explained how to adjust the humidity levels according to user preferences, as well as provided tips on properly maintaining the humidifier for its longevity. While wet film humidifiers are not designed for air quality improvement, they can help preserve goods by maintaining the appropriate humidity level.

Overall, wet film humidifiers offer several advantages, including their relatively low cost, high efficiency, low noise, and low energy consumption. With their ability to preserve goods and prevent damage caused by excessive moisture or dryness, wet film humidifiers are an essential tool for industrial settings where precise humidity control is required.

If you’re looking for an efficient and cost-effective way to control humidity levels in your warehouse, storage, or electronic workshop, a wet film humidifier may be just what you need. Not only can it help preserve goods and prevent damage caused by excessive moisture or dryness, but it’s also easy to set up and maintain.

We encourage you to give it a try and share your experience with the device. If you have any questions or concerns, don’t hesitate to contact us. We’re always here to help and provide you with the best solution for your humidity control needs.